Production Blenders

Pharmatech are world leaders in the design and manufacture of blenders and blending systems for powders and granules in the pharmaceuticals industry.

Their philosophy is simple - to build a blender or system that suits your application rather than forcing your current process to accommodate your new blender. Designed to be as user-friendly as possible, Pharmatech's experienced designers work alongside pharmacists who have years of experience working in pharmaceutical production environments.

The range of Production Blenders available includes V-Shell Blenders, Double Cone Blenders, IBC Blenders and Drum Blenders.

V-Shell Blenders

V-Shell Blenders are designed to provide an intensive mixing action through rotating, repeatedly dividing and mixing the product together. Single or double plinth designs are available and any size up to 6000 litres is possible. Advantages of single plinth designs include the machine taking up less space and allowing for easy through-wall installation.

V-Shell Blenders can be manufactured to any specification, with the most common designs being Symmetrical and Asymmetrical.

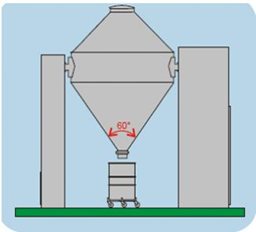

Double Cone Blenders

Double Cone Blenders provide a gentle, energy-efficient blending action ideal for fragile and delicate materials as often found in the pharmaceuticals industry. They are usually designed as fixed shell blenders where the Double Cone is permanently attached to the support plinths.

Pharmatech can manufacture Double Cone Blenders to any specification. For optimum performance, Pharmatech recommends a 60° internal angle in the lower cone to ensure efficient blending and product discharge.

FEATURES

|

-

Any size up to 6000 litres

-

Stainless steel design

-

Maintains Good Manufacturing Practice

-

Single or Double Plinth designs

-

Free-standing or through-wall

-

Ex-rated to any standard

-

Full Validation Documentation available

|

Intermediate Bulk Container Blenders

Due to their irregular shape, IBCs are highly efficient containers for blending. The main advantage of IBCs is that the blender cannot become contaminated by the product as IBCs are charged and discharged away from the blender. This is especially convenient in multi-product environments where the machine is required to blend a number of different products within a short period of time. As with all Pharmatech blenders, the IBC blenders are constructed using stainless steel and adhere to GMP standards. Suitable for IBCs up to 4000 litres in size, the blenders can be free-standing or through-wall installations.

Available Types of IBC Blenders:

|

C-Frame Blender |

|

|

IBC is clamped using Clamping Bars situated on the side of the IBC. The container is raised before blending begins. |

|

|

|

|

Universal Arms |

|

|

The IBC is fitted with a pair of tubes that fit over the two prongs on the drive unit. Universal Arms are suitable for IBCs up to 1000 litres in size. |

|

|

|

|

Cage Blender |

|

|

The Cage Blender is designed to secure the IBC at special location points fitted to the top and bottom. |

|

|

|

|

IBC Hoist Blenders |

|

|

IBC Hoist Blenders allow the IBC to be raised after blending, discharging the product into the next machine in the line. This offers versatility and suits environments where space is limited. |

Drum Blenders

Drums are easy to handle, less expensive than most blending containers and ensure good blending performance. Pharmatech manufacture stainless steel Drum Blenders to fit drums of up to 500 litres, with the machines adhering to GMP standards.