Spheronization

SpheronizationTM relates to the manufacture of small round pellets with a limited size spread within a batch. The Pellet sizes (sometimes called micropellets or spheroids) can be made within tight size ranges between 0.5mm and 2.0mm in diameter. SpheronizationTM is also sometimes known as spheroidization, pelletisation or marumerisation.

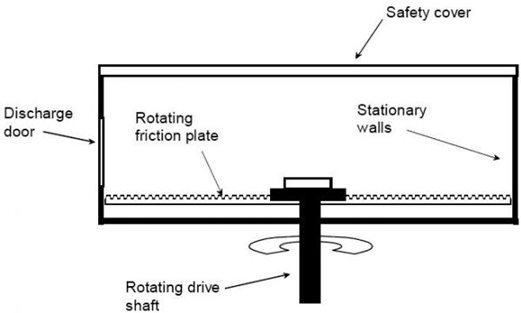

We offer Bench-Top Laboratory Spheronizers, Pilot Scale/Small Production Spheronizers, Medium and Full-Size Production Spheronizers that operate on the basic principles shown below:

ADVANTAGES OF SPHERONIZATION FOR THE PHARMACEUTICALS

INDUSTRY

|

-

Enables easy mixing of otherwise incompatible formulations

-

Reduced risk of dose dumping

-

Easy formulation and mixing of otherwise incompatible formulations

-

Manufacture of modified release solid dose formulations

-

Allows for uniform coating and accurate free flow filling into capsules

-

Less variable bioavailability

-

Reduced risk of local irritation in gastro-intestinal tract

-

Offers dust free packaging. Handling procedures can be important marketing and product features within the pharmaceutical, food and cosmetic industries.

-

Eliminates dust within agro-chemical, pigment and catalyst industries, reducing risk of toxic, environmental and explosive hazards

-

Improves processing consistency and productivity by using consistent free-flowing product

-

Reduces product settlement in transport by spheronization of powder products prior to packaging

|

Bench-top Laboratory Spheronizers

|

|

For the production of spheroroids in the laboratory, We offer our Bench-top Laboratory Multi Bowl Spheronizers (MBS). Spheronizer bowls are available in different diameters including 250mm, 120mm, 85mm and 60mm. All bowls are interchangeable on the same base and can be purchased as and when you need them. This provides customers with a cost-effective way to work with a wide range of batch sizes, as anything from 1g to 1kg can be spheronized. |

AVAILABLE OPTIONS

|

-

PTFE coating on drum and discs

-

Automatic run timer

-

Fines air

-

Spheronizer discs with different cut patterns

-

Heating/cooling water jacket on the spheronizer drum

-

Full IQ/OQ pharmaceutical packages

|

Pilot Scale/Small Production Spheronizers

|

|

The Spheronizer 380 is a floor-standing pharmaceutical machine designed for large scale experimental use and small quantity batch production. Small enough to be moved on fitted castors, but also sturdy enough to be considered production equipment, the Spheronizer 380 is designed to work as companion equipment with the 35 Screen Extruder or the 40 Gear Extruder.

The level of automation and style of construction can be adapted according to your specific needs.

|

Production Spheronizer 500

|

|

The Spheronizer 500 is a floor-standing production machine capable of medium scale production with batch sizes of 1 - 10 kg. As with the Spheronizer 380, the 500 machine is fully transportable between locations but large enough to be a full-scale production machine. The Spheronizer 500 can be run continuously and is companion equipment for the 35 Screen Extruder, 40 Gear Extruder and HT1 Screw Extruder.

|

Full-size Production Spheronizer

|

|

For continuous bulk production applications, We offer their 700 system for the manufacture of pharmaceutical pellets (spheroids).

Typical batch weights for such machines vary between 5 kg - 20 kg. For some products the required process time might be as little as 30 seconds, with average process times of 4-7 minutes.

With over 40 years experience, we have developed spheronizers that require minimal maintenance and consumption of renewable parts. With specifications allowing the Spheronizer 700 to run continually, Arcon are still servicing and upgrading production spheronizers that have been in constant use for many years.

|

FEATURES

|

-

GMP design

-

316 stainless steel construction

-

Designed and built to meet individual requirements

|