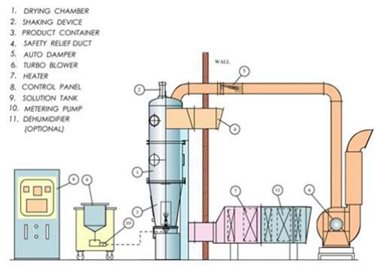

Fluid Bed Dryer-Granulator-Coater

Arcon supplies highly efficient Fluid Bed Dryers that fully comply with GMP standards for the Food and Pharmaceutical industries. If required, Fluid Bed Dryers can offer a complete solution for mixing, granulating, drying, coating or pelleting in a single machine, saving floorspace and reducing production time.

The material is completely fluidized in the robust, easy-to-clean drying chamber and as a result drying times are up to 20 times faster than conventional oven drying. The average drying time is 30 - 45 minutes per batch, with working capacities of between 0.5 - 500 kgs/batch. Please see the table below for technical capabilities of the Fluid Bed Dryer range:

TECHNICAL SPECIFICATIONS

|

Working Capacity

(based on B.D. 0.5g/c.c.) |

0.5 - 500 kgs / batch |

|

Volume of Container |

7 - 600 l |

|

Fan Motor |

2.2 - 45 kW |

|

Air Flow |

6 - 160 CMM |

|

Heating Volume |

8500 - 230 000 k/cal per hour |

Additions to the basic Fluid Bed Dryer allow for Top Spray Granulation, Bottom Spray Sugar/Film Coating or Side Spray Granulation/Film Coating suitable for both organic solvents and aqueous solutions.

OPTIONAL FEATURES

|

-

Dust collection system

-

Powder leakage detection

-

CIP or WIP automatic cleaning function

-

Dehumidifier for thermo-sensitive materials

-

Explosion-proof design for organic solvents

-

Vacuum discharge for closed-type operations

|